Cryogenics

Lehigh Equipment Company has been a leading supplier of liquid cryogenic and industrial gas equipment since 1998.

The scientific definition of cryogenics, according to Linde.com, Cryogenic Liquefied Gases are also known as Refrigerated Liquefied Gases or Deeply Refrigerated Gases and are commonly called Cryogenic Liquids. Cryogenic Gases are cryogenic liquids that have been vaporized and may still be at a low temperature.

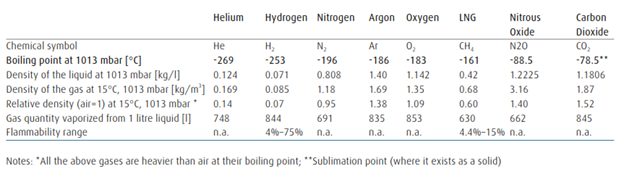

Cryogenic liquids are used for their low temperature properties or to allow larger quantities to be stored or transported. They are extremely cold, with boiling points below -150°C (-238°F). Carbon dioxide and Nitrous oxide, which both have higher boiling points, are sometimes included in this category. In the table you may find some data related to the most common Cryogenic Gases.

Cryogenic Equipment Market

A recent industry report projected the global cryogenic equipment market to hit 17.1 billion by 2025. There is a tremendous need within industrial processes for the strategic use of liquified gases. There are some processes within markets such as machining, where traditional lubricants used for cooling aren’t as effective, making cryogenics a superior choice.

Markets Served – Cryogenic Equipment Usage

Growth markets with increasing needs for cryogenics applications include the following sectors;

1) Healthcare

Mid-size hospitals have a growing need for improving their current oxygen systems with more efficient, safer and lower cost alternatives like using bulk storage tank systems to deliver medical grade oxygen. The need for an uninterrupted oxygen supply is critical in a medical environment, both primary and as a backup supply. The benefits of using bulk liquid storage tanks to maintain supplies of oxygen or other gases can provide cost savings for hospitals by using an upgraded system versus a manual process of moving portable tanks to provide. Learn more about how cryogenic liquids can increase efficiencies for hospital and medical facilities.

2) Food & Beverage

The food and beverage industry is trending with increasing needs of safety, leading to more interest and application of cryogenic freezing. There are many benefits of freezing using cryogenics, some of the most important include the non-altering outcome, after application on food quality as well as coloring of the products. Liquid nitrogen is one of the most popular types of cryogenic gases to preserve baked food (cakes, cookies, etc.), meats (hamburger, chicken, etc.), vegetables and prepared foods. Learn more about how cryogenic liquids can increase efficiencies for food and beverage manufacturers and providers.

3) Manufacturing

Cryogenic manufacturing process examples include machining, forming and grinding, where the cooling application helps improve the speed and performance of machines and tools. Running certain processes under extremely cold temperatures can increase efficiencies and reduce costs. Manufacturers and industry specialists have researched and explored the practical applications and improvement benefits of the effects of cryogenic temperatures for the last several decades. Learn more about how cryogenic liquids can increase efficiencies for manufacturers and other industry providers.

4) Metallurgy

According to ThoughtCo.com, “the process of cryogenically treating a metal part involves very slowly cooling the metal using gaseous liquid nitrogen. The slow cooling process from ambient to cryogenic temperatures is important in avoiding thermal stress.” Improving processes using applications of cryogenics has become more widely adopted and commonplace. Learn more about how cryogenic liquids can increase efficiencies within the metallurgy industry.

If you’re ready to start comparing new and refurbished equipment or leasing options for your market, browse our inventory of bulk storage tanks, transports, portable storage and vessels and request your quote today. Lehigh’s equipment is in stock and ready to ship.